Capabilities

Continuous honing of capabilities has been the key to our diversification, ranging from Shipbuilding to Heavy Engineering and System Integration to Turnkey Project Execution.

A formidable partner, backed by highly capable, resourceful and motivated teams, across all industries catered to by FF Group.

System Integration:

- Refinery revamp packages, through supplies of Mechanical, Pneumatic, Electrical and Instrumentations products and services

- High Pressure Fluid Control & Systems

- Turnkey projects onboard Ships and Submarines

- Electronics and Instrumentation Solutions

- SPMs for Defence and Aerospace applications

Design and Engineering:

Experienced in-house design & engineering teams ensure design specific to client and/or process licensor needs while complying with international codes and standards.

- Heavy Engineering and Fabrication

- Exotic Materials

- Computational Fluid Dynamics

- Actuation and Control Systems

- Heat Transfer

Fabrication:

- Captive Shipyard, Construction of Marine and Naval Vessels

- Mega Blocks Fabrication- seamless scalability across country.

- Heavy Engineering and fabrication

- Highly experienced and qualified in-house welding teams

- Clean Room facilities

|

|

|

Certifications:

- ASME U & R stamp

- DIN 2303 standard for welding

- EN 15085 for railway welding applications

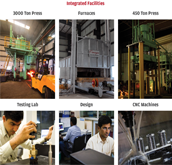

Forging and Heat Treatment:

Forging of special materials such as NAB, Titanium, Maraging Steel, Monel, Super-Alloys, Inconel and others and use of special processes such as Isothermal Forging.

Machining:

Machining facilities include an array of CNC – Turning & Milling including 5-Axis machines, CMM, Jig boring machines, Conventional heavy duty horizontal boring machines and lathes

|

|

Electrical and Electronics:

Capabilities in Technology Development, Conceptual System Design , Prototyping and manufacture in areas of

- Optical, Magnetic and Electro Mechanical sensors

- Signalisers – both analog and digital

- Electric actuators for various applications.

Card level repair and maintenance of communication and other equipment

Testing facilities:

In-house dedicated QA/QC team is supported by metallurgists and other field experts and NDT facilities

|

|